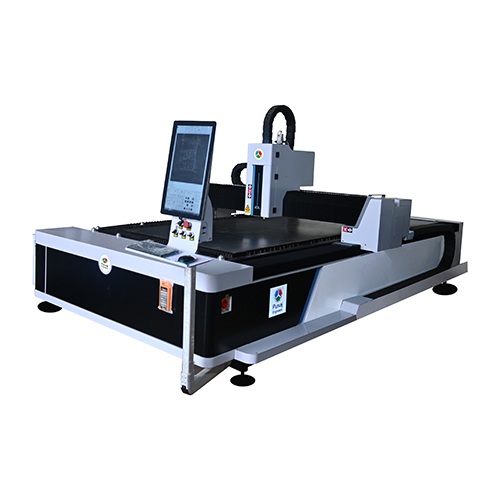

3015ex.35 Laser Cutting Machine

Product Details:

- Material Metal

- CNC Or Not CNC

- Computerized Yes

- Automatic Grade Automatic

- Cooling Mode Water Cooling

- Control System Human Machine Interface

- Voltage 220-440 Volt (v)

- Click to View more

X

3015ex.35 Laser Cutting Machine Price And Quantity

- 1 Unit

3015ex.35 Laser Cutting Machine Product Specifications

- Yes

- High Performance

- Water Cooling

- 220-440 Volt (v)

- CNC

- Metal

- Human Machine Interface

- Automatic

3015ex.35 Laser Cutting Machine Trade Information

- Cash in Advance (CID)

- 10 Unit Per Month

- 2-3 Week

- All India

Product Description

A Fiber Laser Cutting Machine is widely used for high-precision metal cutting. It utilizes a fibre laser source to deliver a concentrated beam for fast and efficient cutting of various materials like stainless steel, mild steel, aluminium, brass, and copper.

Purvajs Fiber Laser Cutting Machine key features

Laser Source & Power

- Fiber Laser Generator: High-efficiency laser source

- Power Range: Typically, from 1500W to 60 kW, depending on application.

High Cutting Speed & Precision

- High Accuracy: -/+ 0.02mm precision with minimal heat-affected zones (HAZ).

- Non-Contact Cutting: Ensures smooth, burr-free edges without tool wear.

Cutting Capabilities

- Materials: Stainless Steel, Mild Steel, Aluminium, Copper, Brass, Titanium, and more

CNC Control System

- Advanced CNC Controller: User-friendly touchscreen for precise operation.

- Auto Nesting Software: Optimizes material usage and reduces waste.

- Real-Time Monitoring: Displays cutting parameters and diagnostics.

Automatic Features for Efficiency

- Auto-Focus Laser Head: Adjusts focal length for different materials and thicknesses.

- Automatic Sheet Loading & Unloading System (Optional): Improves productivity.

- Dual Pallet Changer (Optional): Allows continuous cutting for high-volume production

Safety & Environmental Features

- Fully Enclosed Design (Optional): Protects operators from laser radiation.

- Fume Extraction System: Removes smoke and dust for a clean work environment.

- Protective Glass & Safety Sensors: Ensure operator safety.

Energy Efficiency & Low Maintenance

Benefits of Fiber Laser Cutting Machines

- High-Speed, High-Precision Cutting

- Lower Operating Costs & Energy Consumption

- Minimal Maintenance & Long Laser Life

- Superior Edge Quality & Versatility in Materials

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese